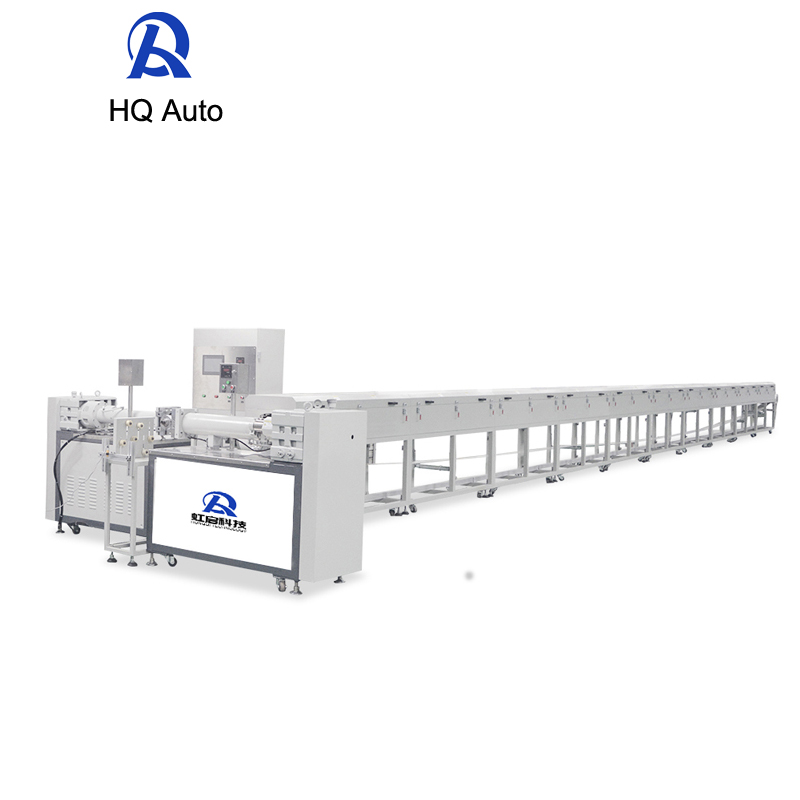

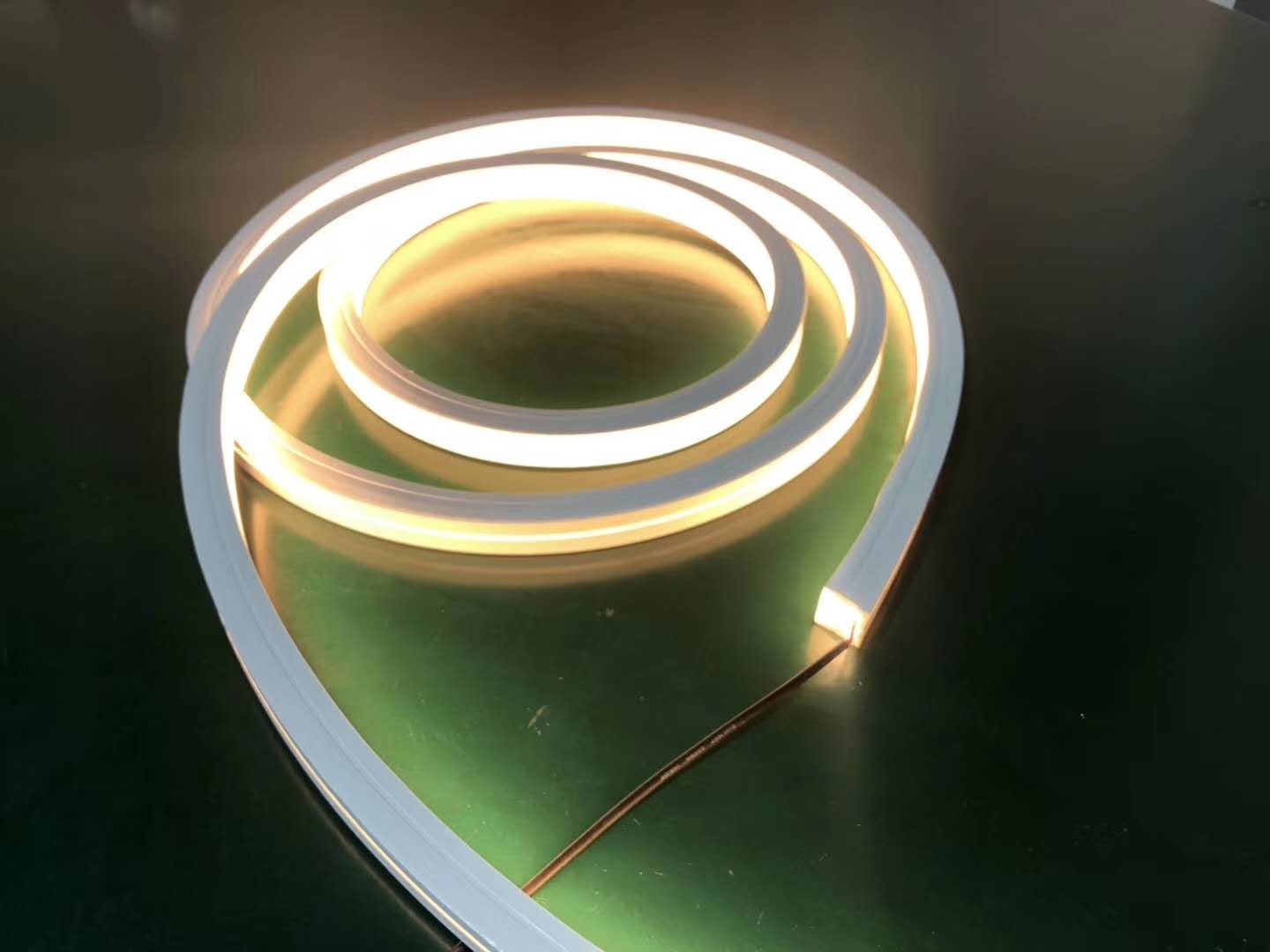

LED Soft Strip Silicone Extrusion Machine Neno strip extruder machine/silicone led lights machine

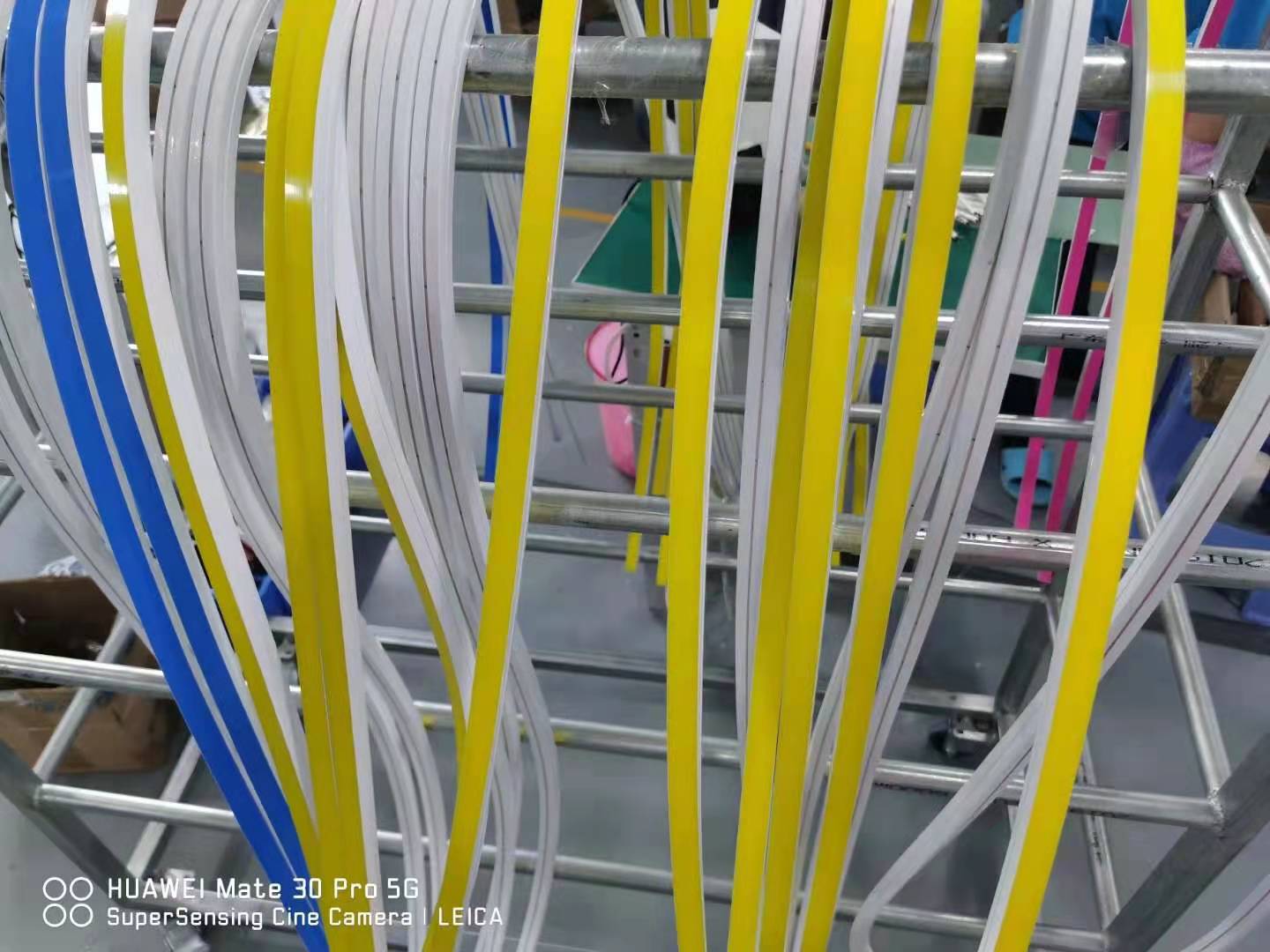

Application range of LED flexible lamp belt silicone extruder production line:

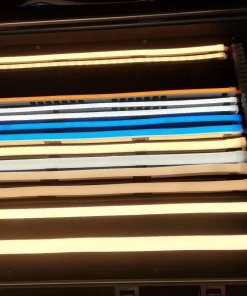

1. LED soft light strip

2. Neon strip

3. High and low voltage light strip

4. Optical light strip

Layout of HQ- JC6565/JC8080 silicone extrusion machine

![]()

| Name | SKU | QTY |

| Horizontal Silicone Extruder 65W | CJC-65W/OR80W | 2 Set |

| Raw Material Mixer | KLJ-9C | 1 Set |

| Water Cooler | SLJ-3P | 1 Set |

| Baking Tunnel | HW2000-250 | 10 Groups |

| Extruding Mold | Two Color | 1 Set |

| Smart Take-up Rack | FXJ-630 | 1 Set |

| Waterproof Plug Forming Machine | MY-7550 | 1 Set |

| T-shaped Extruder Head | Y135T | 1 Pcs |

| High-Temperature Setting Furnace | HW530-600 | 1 Set |

Extruder Machinesilicone extrusion

![]()

| ITEM | SPEC |

| Screw Diameter | 65mm/80mm |

| Screw and Shell Material | 38CrMoAl |

| Compression Ratio | 2.5:1 |

| Thread Specification | Linear thread, not equal to the same distance |

| Gearbox | Special designed gearbox for silicone extruder |

| Motor | High-Efficiency Variable Frequency Motor |

| Frequency Converter | High performance vector converter |

| Maximum Extrusion | >35KG/H |

| Power | 11.5kw |

| Rotating Speed | 50rpm Max |

| Dimension | 1500*700*1250mm |

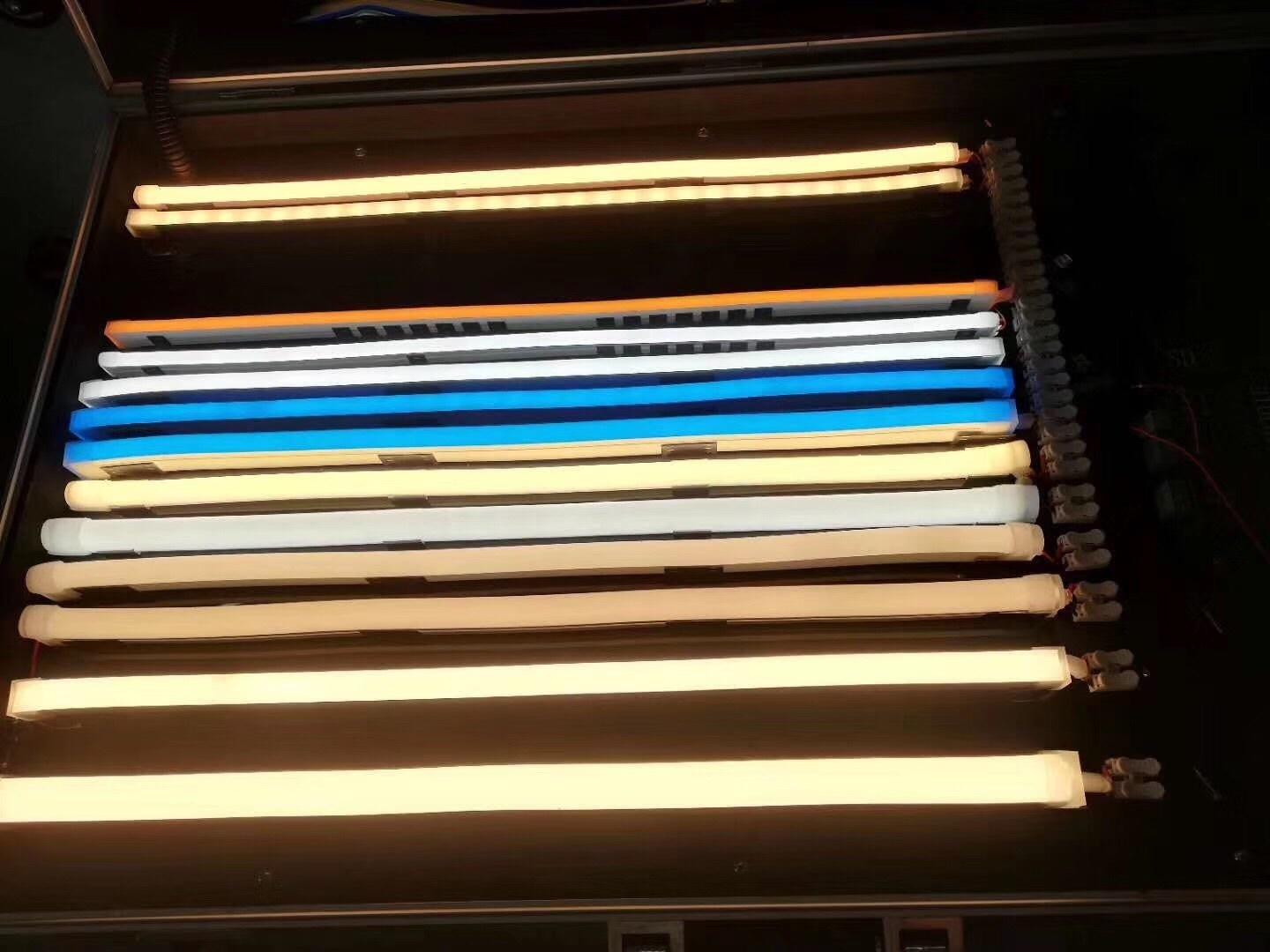

Vulcanizing Channel

![]()

| Model | HW2000-250 (20M) |

| Power Supply | 380VAC 50HZ |

| Dimension | 2000*460*1250mm |

| Max Power | 4.8KW |

| Temperature | 250℃ |

| Heating Speed | (25-200℃)<5MIN |

| Conveyor Belt | Teflon, Stainless steel |

| Speed Mode | Frequency |

| Tunnel Material | Inner layer 304 stainless steel, outer layer high-strength sheet metal for the baking process (can be made of all stainless steel) |

| Insulation Material | Glass fiber |

LED Board Coating Machine

![]()

To make the strip surface coated with a layer of surface treatment agent, so that silica gel and strip can be solid bond together

Bottom coating amount: 0.3-0.5g/M (depends on the number of lamp beads, plate width, solid core and hollow core products)

Coating method: atomized coating

Length 800*Width 400 *Height 1500mm

Silicone Mixing Machine

![]()

| Model | KLJ-9C |

| Power Supply | 380VAC /50HZ |

| Dimension | 2800* 1300*1400mm |

| Roller Diameter | 230mm |

| Power | 11KW |

| Maximum Spacing | 10mm |

| Rotating Speed | 18rpm |

| Cooling Method | Water cooling |

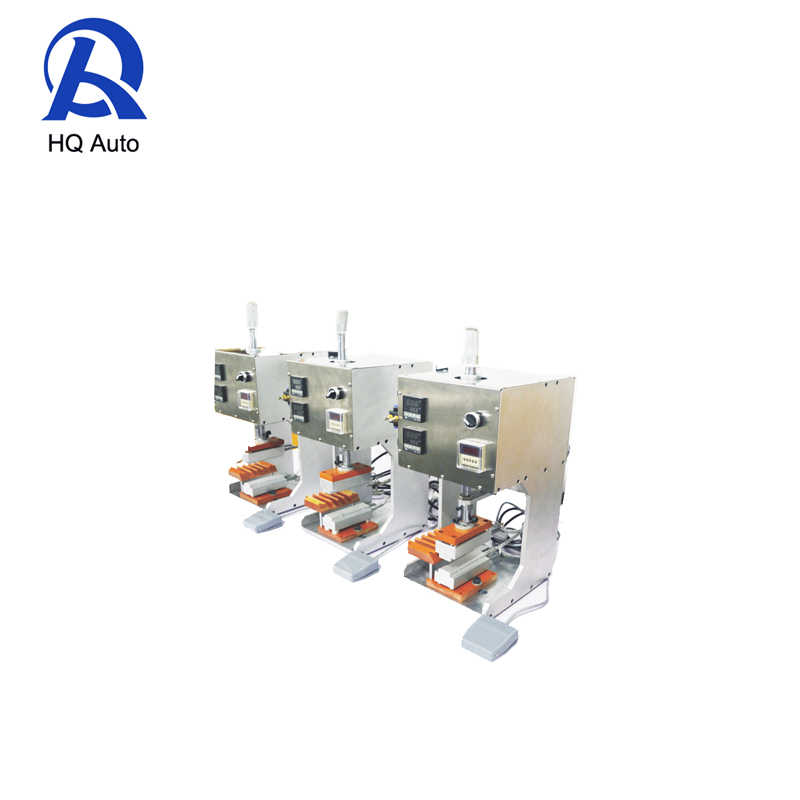

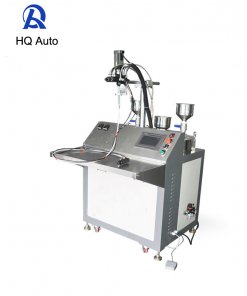

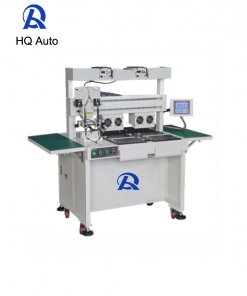

Repairing Machine

![]()

| Model | MY-7550 |

| Power Supply | 220VAC/50HZ |

| Power | 3200W |

| Air Pressure | 0.5MPa |

| Dimension | 400*400*850mm |

| Working Temperature | 200℃ |

| Clamping Time | 1-99.99H |

Pay-off Rack

![]()

| Model | FXJ-630 |

| Working Diameter Range for Reel | 350-630mm |

| Power Supply | 220V/50HZ |

| Rotating Speed | 60rpm max |

| Weight Capacity | 40kg |

| Sensing Method | Infrared reflection induction |

| Motor | 200W |

Cooling Machine

![]()

Cooling method: air-cooling

Power Supply: AC 380V 50Hz

Power Consumption: 2600W

Working capacity: At the same time to load 1* Refine machine, and 2*Extrusion Machine

Length 1200 * Width 600 * High 1100mm