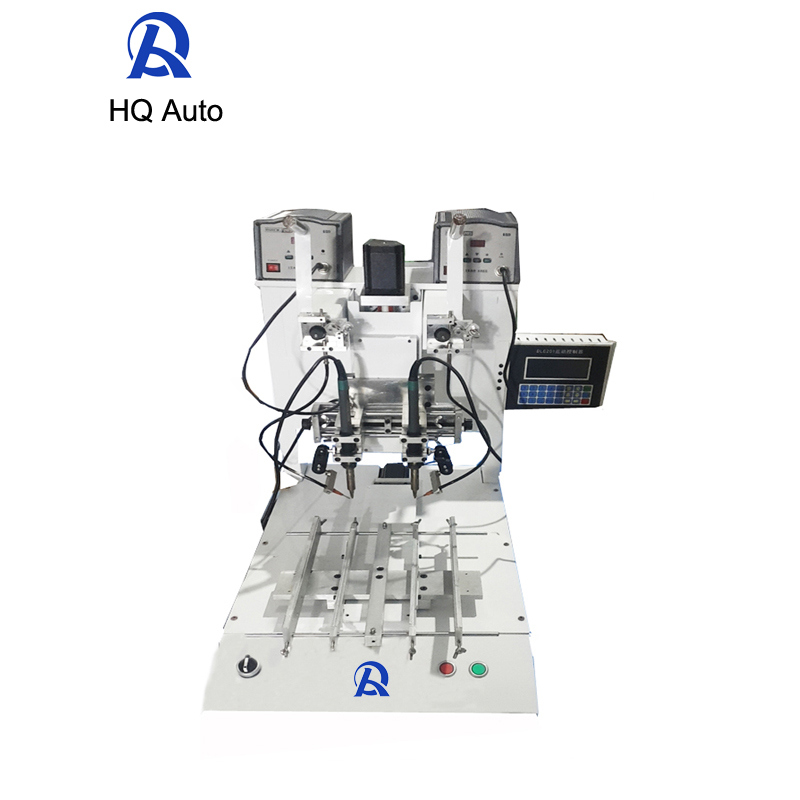

LED soft light plate soldering machine,LED flexible light bar welding machine,LED Strip Soldering machine

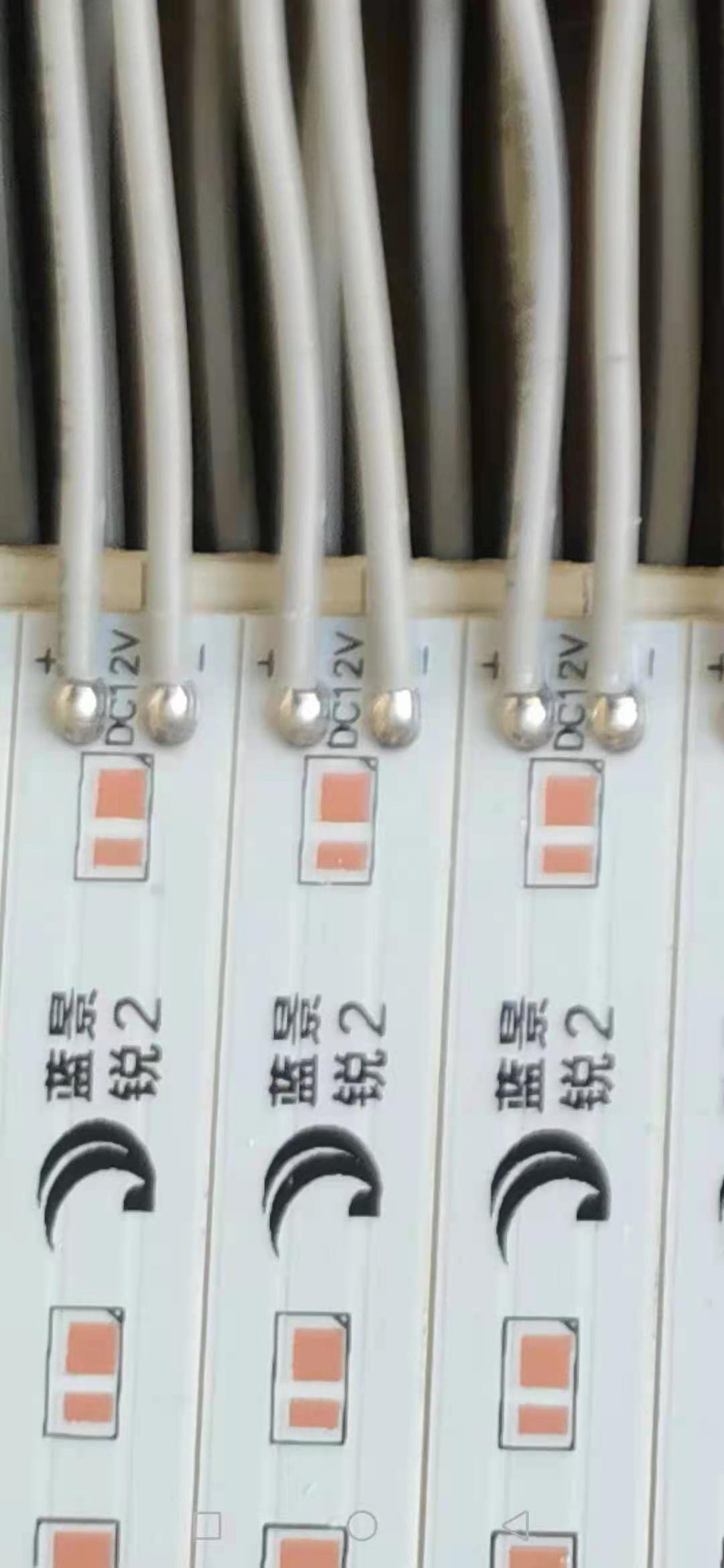

Application range:Suitable for LED module wire bonding machine, exposed light string bonding machine, light string bonding machine, soft light strip wire bonding machine, light strip wire bonding machine, light bar wire bonding machine, USB wire bonding machine, power drive, switch Products with the same solder joints such as wire bonding machines.

Main features:

1. It can replace manual soldering work for various solder joints, such as spot welding and drag welding. Solve the phenomenon of uneven solder joints and false soldering in manual welding.

2. It can replace the manual process and optimize the quality control.

3. And can improve efficiency and save manpower. The operation is simple, and beginners can also achieve the welding effect of skilled workers.

4. Dedicated program, simple programming, can easily adapt to changes in product models and production lines

5.LED module: 3000~5000PCS/hour; LED light string 2000~3000PCS/hour

6.The soldering speed is fast and the efficiency is high. A soldering machine can save 4-5 people.

7. Save tin wire and waste of tin wire.

8. The solder joints are uniform and consistent,

9. High-power heating controller to ensure the stability of continuous soldering.

10. Double soldering head, one action to solder two soldering points.

11. It adopts double guide rail structure, which is more stable than similar machines.

Specification

| NO. | Item | Parameter |

| 1 | Device name | LED soldering machine for soft light strip plate/LED moulds |

| 2 | Model | HQ-700 |

| 3 | control mode | Belt rotation |

| 4 | Welding head | 2 iron heads work at the same time |

| 5 | Working stroke | X axis260MM,Z axis 120MM,platform 1000MM |

| 6 | Repeatability accuracy | ±0.05mm |

| 7 | Equipment power | 350w |

| 8 | Power Supply | 220V,50-60HZ |

| 9 | weight | 45KG |

| 10 | Size | 80*60*50(L*W*H) |