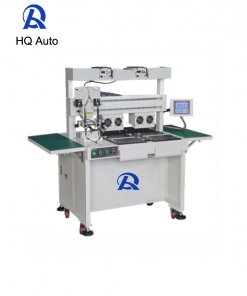

SMT automatic loading and unloading machine PCB board feeder and loader machine

The SMT automatic production line sends the board to use, no need to touch the PCB board by hand, which better protects the PCB board. It can also set the number of lifting grids. This machine has high lifting precision, automatic feeding and discharging frame, and fault (tone, color) alarm functions. It is a necessary equipment for realizing full-line automation and high output.

Main Features:

1.The lifting power adopts gear reduction brake motor.

2.The lifting drive adopts 30MM hard shaft guide rail, equipped with precision ball screw drive.

3.The lifting table is formed by one-piece casting, with high precision and not easy to change.

4.The conveying track adopts special profile with anti-collision stainless steel shaft.

5.The conveyor chain adopts PC40 black chain.

6.Using Siemens PLC, equipped with easy-to-operate touch screen control interface.

7.Equipment status indication: three-color light with buzzer + touch screen alarm code display.

8.The photoinductor adopts OMRON sensor for sensing.

9.An anti-split sensor is installed at the outlet to protect the PCB from lifting the splint when the PCB is not fully pushed out.

10.Upper and lower pneumatic clamps can ensure the accurate position of the material frame

11.The push plate cylinder uses a rod cylinder to push the PCB out of the material frame.

12.The thrust of the push plate cylinder can be adjusted as needed to prevent excessive thrust from damaging the PCB.

13.Equipment shells are all electrostatic sprayed, and the surface is durable without paint falling off.

Specification:

| Gas source | 0.5~0.7Mpa | |

| power supply | AC220V | |

| frequency | 50/60HZ | |

| power | ≤0.4KW | |

| Use environment | 0-55℃ | |

| Working height | 900±20mm | |

| Adapt to PCB board size | Max: Length350mm*Width 250mm Min: Length 50mm*Width 50mm |

|

| PCB board transfer direction | Left to right | |

| Closing time | 10S | |

| Refueling frame time | 40S | |

| Equipment weight | 260KG | |