LED soft light plate soldering machine,LED flexible light bar welding machine,LED Strip Soldering machine,Welding machine

Application range:suitable for LED monochromatic lamp, 5050RGB light string, , 5050RGB/3528/S type lamp string, various high and low voltage light strips, light bars and other products.

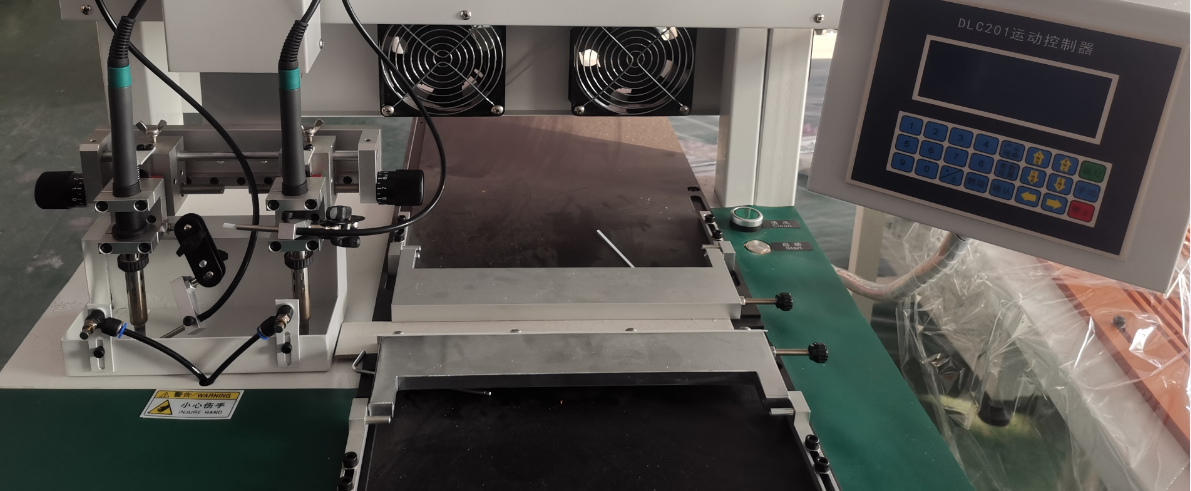

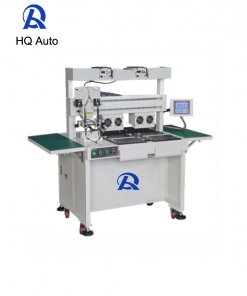

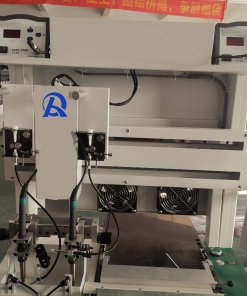

The soft light bar soldering machine is a dedicated 5 meter LED light bar welding automation equipment. The equipment is designed according to the depth of the 5 meter LED characteristics. It replaces the manual soldering work of various solder joints and solves the problem of manual welding. Uneven solder joints, virtual soldering and other phenomena, and compatible with a variety of LED flexible light bar size welding, simple operation, high practicability, stable quality and greatly improved efficiency.

Main features:

- Simple programming,Easy operate,new staff can achieve the welding effect of skilled workers

- Welding speed, high efficiency with double head, a solder machine can save 5-6 people

- Save tin wire, good consistency of solder joint

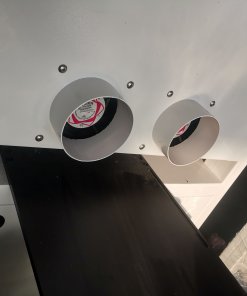

- High power heating controller ensures the stability of continuous welding

- Multi axis manipulator, advanced motion control algorithm, to improve the kinematic positioning accuracy and repeatability accuracy

- According to the professional design of the lamp batten, it is convenient for manual feeding and feeding

- Production efficiency: 1800-3000 metres /H

- Specification

| NO. | Item | Parameter |

| 1 | Device name | LED soldering machine for soft light strip plate |

| 2 | Model | HQ-8800 |

| 3 | control mode | 32position DSP |

| 4 | Welding head | 2 iron heads work at the same time |

| 5 | Working stroke | X axis 350MM,Z axis 150MM,platform 1000MM (double working places) |

| 6 | Repeatability accuracy | ±0.05mm |

| 7 | Equipment power | 600w |

| 8 | Power Supply | 220V,50-60HZ |

| 9 | weight | 120KG |

| 10 | Size | 2000*1400*1400(长*宽*高) |

Technical parameter configuration:

| NO | Name | Brand |

| 1 | Control system | independent research and development |

| 2 | Motor | High precision motor |

| 3 | Guide | Taiwan PMI |

| 4 | sensor | Japan:OMRON |

| 5 | Pneumatic components | Air TAC |

| 6 | Power Supply | Meanwell |

| 7 | Welding gun heating mode | High frequency custom welding table |

| 8 | Drive mode | Japan Misumi industrial belt |

Welding effect