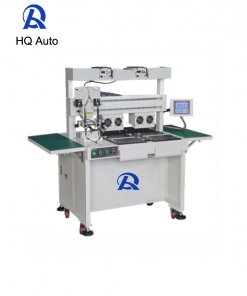

LED esnek ışık çubuğu Makinesi, LED sert çubuk hafif makineli, LED duvar yıkama makinesi, 5M led yumuşak şerit tutkal akıtma makinesi / led ışık tutkal akıtma makinesi

5M AB Tutkal Dağıtım Montaj Hattı Detayları

Otomatik dağıtım makinesine uygun tutkal:

Silika jel, epoksi reçine, AB tutkal, kristal tutkal, PU tutkal vb. gibi çeşitli tutkallar için uygundur.

Otomatik tutkal dağıtıcının uygulama alanları:

Esas olarak 5 metre uzunluğunda sert şerit/yumuşak şerit/tüp için kullanın

El sanatlarında yaygın olarak kullanılır (çıkartmalar, çıkartmalar, etiket kağıdı, karikatür kağıdı, etiketler, fotoğraf çerçevesi albümleri), LED aydınlatma (LED esnek şeritler, LED esnek şeritler, tüpler vb.),

dijital elektronik (devre kartları, PCB), giyim Aksesuarları vb.

Ana özellikler:

1. Çince ve İngilizce çalışma arayüzü, kullanımı kolay, profesyonel hata düzeltme ve kusursuz tasarım.

2. Tutkal çıkış oranı, süresi, hızı ve tutkal miktarı kolayca ayarlanabilir.

3. Yüksek hızlı servo dinamik karıştırma sisteminin bağımsız araştırma ve geliştirmesi, dakikada 3000 devir. Üniform bir karışım sağlayın,

İlk 1-6 tutkal kafası, üretim kapasitesi saatte 1000 metreden fazlaya ulaşabilir.

4. İlk bölünmüş gövdeli ayarlanabilir anlık emme kapatma valfi, yüksek oranlama, anti-çekme, tutkal damlaması konusunda yeni bir atılım,

ve tutkal taşması, yüksek hassasiyetli aşınmaya dayanıklı ölçüm dişli pompası (pompa gövdesi gerektiği gibi seçilebilir) ve güçlü sürekli tutkal çıkışı.

5. Tutkal sızıntısını önlemek için benzersiz döner conta tasarımı.

6. Güçlü düzenlenebilir sistem, titreme olmadan sürekli ve hızlı tutkal dağıtımını gerçekleştirir ve stabiliteyi artırır.

7. Kabloları değiştirmek için programlama süresini iyileştirmek amacıyla birden fazla veri kümesini saklayabilir.

8. Otomatik basınç sensörü, zamanlama boşaltma fonksiyonu ve otomatik temizleme fonksiyonu ile donatılmıştır.

9. Malzeme varilinin çok katmanlı geçiş sistemi ve yüksek hassasiyetli sıvı seviye sensörü alarm sistemi ile donatılmıştır.

Ana parametre

Size daha iyi hizmet verebilmek için size uygun makineler sağlayacağız. Aşağıdaki bilgileri sağlamanız önerilir

Ürünler hakkında bilgi almak istediğinizde bize

| 1 | Tutkal bilgileriniz |

| A | Tek bileşenli mi yoksa iki bileşenli mi? |

| B | tutkal oranı |

| C | Tutkal viskozitesi / Tutkalın özgül ağırlığı |

| D | Tutkalın ilk kürlenme süresi/tam kürlenme süresi |

| e | Tek bir ürün için tutkal miktarı, ve tutkal doldurma işlemine ilişkin gereksinimler (video, resim) |

| F | Makinenin tutkal besleme hacmi ve akış gereksinimleri |

| G | l Tutkal kürleme koşulları (sıcaklık, çevre) |

| H | İki ayrı yapıştırıcının karıştırılmasının reaksiyona girip girmediği |

| BEN | Tutkal ambalajı |

| 2 | Ürünlerinizin resmi/boyutu eğer ürünler çok bedenli ise en küçüğünü ve en büyüğünü göstermek gerekir |

| 3 | müşterilerin diğer özel gereksinimleri |